Given the nature of the raw materials involved, reliable, rapid detection of gas leakage is a vital life-safety need in every petrochemical manufacturing facility. Some of the most dramatic industrial disasters have taken place in these facilities. Fortunately, such incidents are rare due to an intense effort to mitigate their risk by installing certified or listed life-safety detection and mitigation systems.

Whether your facility is manufacturing aromatics or olefins, the products and by-products are flammable. Given the miles of piping and complex manufacturing structures, detecting leaks is a significant challenge. Leaks can occur at piping joints and bends, around worn or damaged seals, be caused by weather action, operational wear and tear or damage to facilities. Manufacturing structures can obstruct the view of the leak by detection devices, slowing the response of the life-safety system.

When it comes to life-safety, you need to utilize rigorously tested and certified detectors for the specific gas or range of targeted gases. Occasionally, the term monitor will crop up in discussions of life-safety systems. Gas monitors are not suitable for life-safety systems. Why? They are designed for an entirely different purpose. Gas monitors measure the amount of gas inside a process. They are programmed to manage the operation of the process, not execute life-safety responses. Additionally, gas monitors are not held to the same performance and reliability standards as gas detectors for life-safety applications. Nor do they need to be.

Gas detectors, on the other hand, are specially engineered to detect the presence of gas in areas where it should not be found. Using sophisticated algorithms and technologies, these detectors can detect gas from leaks rapidly. They are then able to initiate responses by the life-safety system within seconds, or milliseconds, as dictated by the applicable codes required by the Authorities Having Jurisdiction (AHJ).

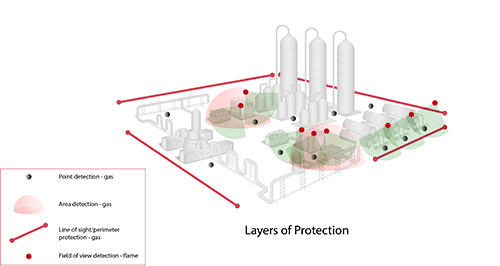

The type of detector you select depends upon the nature of the potential risk. The two basic categories of permanently mounted gas detectors are point and area. Point detectors are an excellent choice where manufacturing structures interfere with area detectors, ability to "see" specific areas. Protecting the perimeter of a facility or area between manufacturing structures is an ideal application for area or line-of-sight (LOS) detectors. Your specific situation may require a combination of both.

For 50 years, Det-Tronics has been providing rugged, reliable and innovative solutions for the life-safety needs of petrochemical facilities around the world. Our products and systems comply with the most stringent standards and requirements of AHJs everywhere. Let our detection experts help you create the perfect life-safety gas detection solution for your petrochemical facility.